Bw-pgy relay protection experimental power supply screen developed and produced by our company, dc adjustable part through the voltage regulator, rectification transformer and other precision components, to achieve DC0-250V regulation, easy to use, simple operation, easy to master

Our company can produce all kinds of intelligent power screen, AC power distribution screen, watt-hour meter screen, transmitter screen, accident lighting switching screen, auxiliary relay screen, PT interface screen, switch cabinet, all kinds of stainless steel terminal box and all kinds of non-standard screen.

Bw-ljp intelligent power screen is our company according to the market and customer needs to develop products. The product is suitable for the intelligent distribution system of substation, power plant, etc., to provide reliable and stable AC power supply.

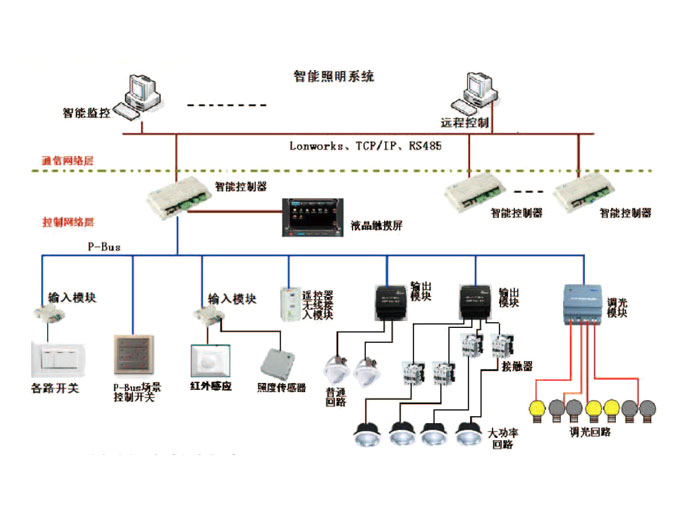

Intelligent lighting control system is composed of central controller, main communication trunk, branch, information interface, intelligent lighting control terminal and so on. Intelligent lighting control terminal is composed of control panel, controller and other units.

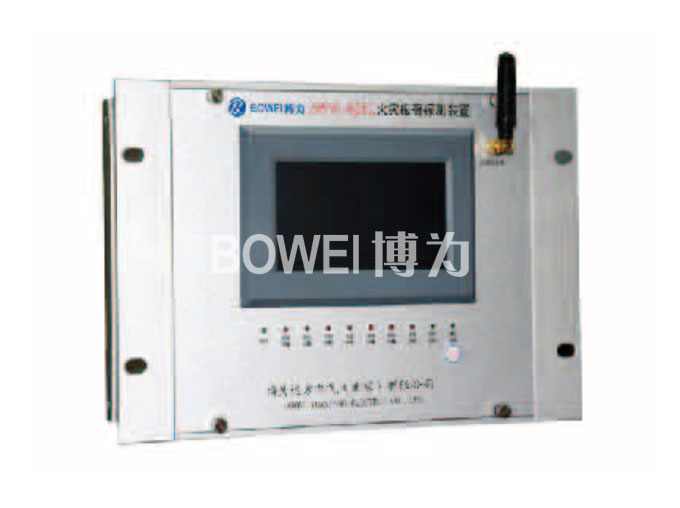

Products are mainly composed of residual current transformers, wireless temperature measurement, infrared temperature measurement, optical fiber temperature measurement, smoke detection sensors, monitoring devices.

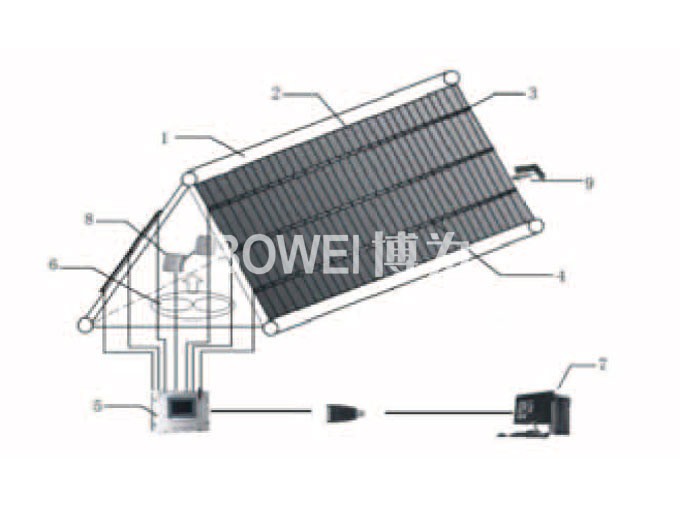

Air cooling unit cold end security and optimize system mainly through the empty cold coagulation (cooling tube bundle temperature field to realize online monitoring of condensation in the air cooling system (cooling), are installed on the temperature measurement sensor

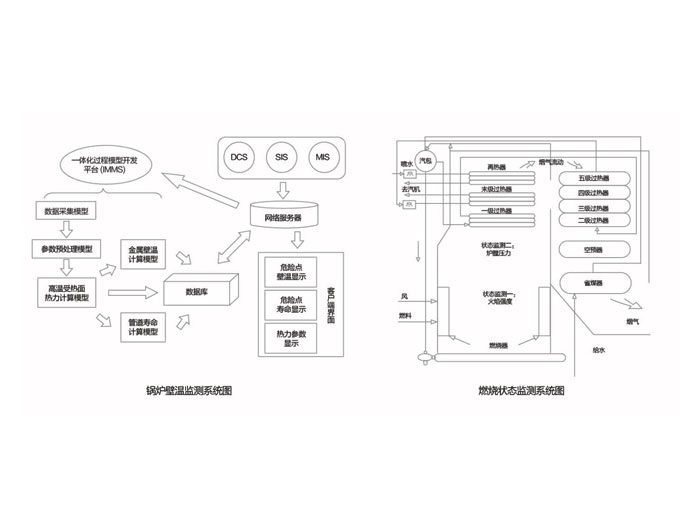

The reliability and health level of power plant equipment are the basis of safe production and economic operation. The equipment management of domestic power generation enterprises generally follows the principle of "prevention first, comprehensive treatment, planned maintenance".

Power plant boiler is high temperature and wall temperature monitoring system in power plant distributed control system (DCS), original plant-level supervisory information system (SIS) and plant-level data management information system (MIS), on the basis of process model by means of - body development platform (IMMS)