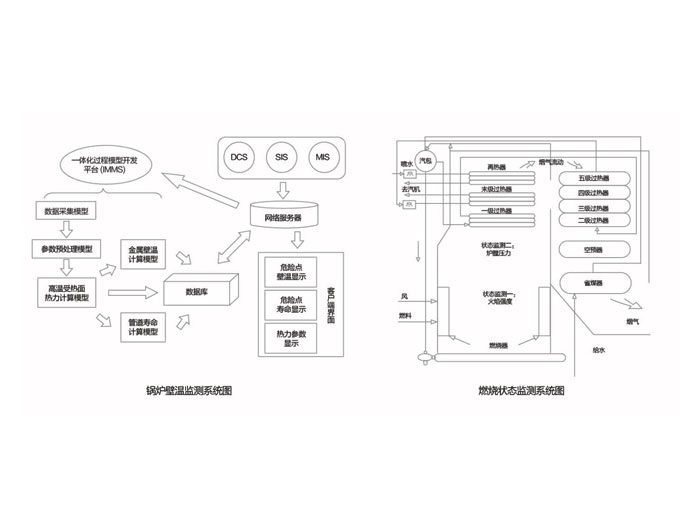

Power plant boiler is high temperature and wall temperature monitoring system in power plant distributed control system (DCS), original plant-level supervisory information system (SIS) and plant-level data management information system (MIS), on the basis of process model by means of - body development platform (IMMS), a mathematic model of the high temperature heating surface and the metal wall temperature calculation model of pipeline life, The obtained parameters are then returned to the interface of the power station network server and client. In the IMMS modeling process, parameters required by relevant calculation are written, such as boiler structural parameters, coal quality parameters, thermal calculation thermal physical parameters and system control parameters, etc. Then, the wall temperature and service life of different positions of heating surface can be obtained through the original monitoring data of power station.

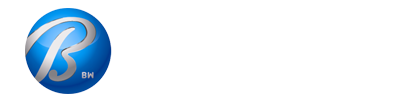

It is an important condition and guarantee for the safe and economical operation of boilers to rationally configure the concentration of pulverized coal at the nozzle and the wind speed at the outlet of the burner. The on-line monitoring system has reliable measuring components, accurate signal processing, intuitive and practical screen, which can guide combustion and adjust the air powder evenly and reasonably. The technology has reached the advanced level in China. It provides conditions and basis for operators to monitor the wind speed and coal powder of each burner and to optimize and adjust the combustion in time and effectively.

Main functional features

● Online monitoring of wind speed at the exit of each primary air duct burner.

● Each air duct coal concentration online monitoring.

● To achieve optimal combustion control, to achieve each air duct - times of wind speed I coal powder regulation, balanced combustion.

● Online monitoring of secondary wind speed.

● Boiler heat loss and boiler efficiency on-line monitoring and combustion optimization guidance.

● Use screen monitor to monitor and process the above parameters in real time, and have rich display function of multiple pictures.

● Use the display to compare the primary wind speed and coal powder concentration of the bar chart, guide the boiler wind speed and coal powder concentration level, reduce the smoke temperature deviation, prevent wind, powder caused by boiler fire accident, so that the boiler in a better operating condition.

+86-312-5907779

+86-312-5907779

Home

Home Tel

Tel Product

Product